The Ultimate Guide to Industrial Machinery Crating and Shipping

Everything you need to know about crating and shipping solutions for your specialized machinery.

Introduction

Effective crating not only ensures that machinery arrives in optimal condition but also enhances the efficiency of the entire logistics chain. Use our informative guide to learn everything from choosing the right materials to making sense of shipping laws, ensuring you can send your machinery anywhere, worry-free. Whether your cargo is going across the street or across the ocean, we've got you covered with tips and insights drawn from industry experts.

The Role of Crating in Machinery Logistics

This chapter explores the critical role of crating in machinery logistics, delving into the thorough process of selecting the right materials and designing custom solutions to ensure the safe transit of equipment. From the benefits of onsite crating to the advantages of utilizing professional crating shops, examine how effective crating not only minimizes damage and costly repairs but also optimizes shipping efficiency.

Just as a helmet is essential for a cyclist, crating is crucial for machinery logistics. It serves as the protective gear for machinery during transportation, guarding against various threats that can occur while moving equipment over distances. And it’s not about just grabbing some wood and nails; it’s about selecting the right materials and ensuring proper protection for every step of your machinery’s journey.

The primary purpose of crating is to protect machinery from the numerous hazards it may encounter during transport. These hazards can include moisture, dust, vibrations, and impacts from handling and shifting loads. Crating provides a sturdy, secure environment for machinery, often customized with padding and supports tailored to the specific needs of the equipment. This customization ensures that even the most sensitive parts are safeguarded against potential damage.

Onsite vs. offsite Crating

Onsite Crating Benefits:

Crating your machinery directly at your facility can be convenient and efficient. There’s no need to transport unwieldy, heavy equipment to another location, which saves you time and reduces the risk of damage during transit. Onsite crating also allows for custom solutions tailored to the specific dimensions and needs of your machinery, ensuring a perfect fit and superior protection.

Benefits of Using a Crating Shop:

Opting to bring your machinery to a professional crating shop can be advantageous too. These facilities are equipped with all the tools and materials to build a robust crate, often with more precision and expertise than what might be available onsite. This can be particularly useful for delicate or extraordinarily high-value equipment, where additional safety measures during crating can provide peace of mind.

While the initial costs of high-quality crating may seem high, the long-term savings are significant. Effective crating reduces the risk of damage to your specialized machinery during shipping, which in turn minimizes costly repairs and replacements upon arrival. Crating can be designed to optimize space within shipping containers or transport vehicles, potentially reducing shipping costs by allowing more items to be transported simultaneously.

Crating Essentials

When it comes to shipping valuable machinery, choosing the right type of crate is not just a practical necessity—it’s the backbone of safe and secure transport. In this chapter, we'll discover the essentials of custom crating solutions, ensuring your products not only reach their destination intact but also comply with global shipping standards.

Proper crating not only helps in avoiding damage and costly repairs but also in adhering to international shipping regulations such as ISPM 15 for wood packaging. This compliance is crucial for avoiding customs delays and ensuring a smooth delivery process, maintaining your company's reputation for reliability and quality.

Whether you're transporting delicate electronics or heavy machinery, the choice of materials—from wood to steel—plays a pivotal role in protection and compliance. Your shipment's foundation depends largely on your machinery's specifications and destination. Pallets come in several types, including stringer pallets, which are the most common and offer great support and handling ease. Block pallets, on the other hand, provide more stability and are ideal for heavier loads. For skids, choosing between wood or steel will depend on weight, durability needs, and budget.

The selection largely depends on the specifics of the machinery you are shipping and the destination requirements. Here’s a closer look at the different options and how to choose the best one for your needs.

Pallets:

Pallets are the most common foundation for shipments and come in various designs, each suited to different types of cargo:

- Stringer Pallets: Often used in North America, these pallets are characterized by a frame of three or more parallel pieces of timber (stringers). They are versatile and cost-effective, suitable for a wide range of products.

- Block Pallets: These are typically stronger than stringer pallets, using both parallel and perpendicular stringers to support the load, which allows for more points of entry for forklifts and jacks. This design is ideal for heavy or bulky items.

- Double-Face Pallets: These pallets are finished on both the top and bottom, which offers more stability and allows for the pallet to be flipped and used on either side. They are ideal for heavier goods.

- Single-Face Pallets: Only finished on one side, these pallets are good for lighter loads that won’t be flipped during transport.

Skids:

Skids are similar to pallets but do not have the bottom deck that pallets do. They are excellent for very heavy loads because they sit slightly closer to the ground, which provides a lower center of gravity and better stability.

Wood vs. Steel

- Wood: Wood is more common and generally cheaper. It is also easier to customize for specific sizes and shapes but requires compliance with ISPM 15 for international shipping to avoid pest contamination.

- Steel: Steel pallets and skids are more durable and suitable for very heavy or hazardous materials. They are less susceptible to weather and pests, making them ideal for long-term use and international shipping that involves harsh conditions but are often more expensive.

Selecting the Right Option

The choice between pallets or skids—and whether to go with wood or steel—should be guided by the weight, size, and sensitivity of the machinery, as well as the shipping and handling requirements of the destination. For regular international shipping, durable materials that comply with international standards like ISPM 15 are crucial to prevent shipment rejections and delays.

An example of this is our experience with large, oversized CNC machines that have delicate tin work around their exteriors. Using a wood crate for such machines could lead to flexing, which might damage the tin work. This decision is primarily driven by weight considerations.

Understanding these options allows you to optimize your shipping strategy, ensuring that your machinery is transported safely, efficiently, and in compliance with international shipping standards.

Don’t have time to read this now?

Download a copy of our Crating and Shipping Best Practices guide

Advanced Packaging Techniques for Valuable Machinery

As machinery has become more sophisticated and valuable, the packaging industry has innovated to meet the growing demands for enhanced protection and security during transport. This chapter examines the transformation from basic, rudimentary methods to highly engineered solutions that address the complex challenges of modern logistics. Discover how specialized materials and technologies have replaced outdated practices, ensuring that machinery is safeguarded during transit.

The evolution of packaging techniques over the past decades mirrors the advancements in machinery and technology. As machinery has become more sophisticated, precise, and costly, the packaging industry has had to innovate rapidly to keep pace with increasing demands for protection and security during transport. Over the last few years, there has been a significant shift from more rudimentary methods to highly engineered solutions that address a broad spectrum of logistical challenges.

The Evolution of Packaging Techniques

Fifteen years ago, packaging for machinery often relied on basic materials like standard wooden boxes and simple cushioning materials such as basic foams.

These materials, while providing a basic level of protection, often failed to address more complex needs such as anti-vibration, moisture control, and tailored fit for non-standard machinery shapes. Today, we would be surprised to see if these materials were used as padding in transporting high-value machinery, yet it was once a commonplace material due to its availability and cost-effectiveness.

As machinery has advanced in complexity and value, the materials used in packaging have also become more specialized. Today's materials are designed not only to protect against physical impact but also to address specific threats such as electrostatic discharge, corrosion, and extreme temperature fluctuations. For instance, modern packaging often incorporates advanced polymers and engineered foams that are custom-shaped to fit intricate machinery parts, offering both cushioning and precise stabilization.

As the machinery itself has evolved, so too has the need for more customized and precise packaging solutions. Gone are the days of simpler forms of protection. Custom foam inserts and made-to-measure crating are now standard practices, tailored to the exact specifications of each piece of machinery. This level of customization not only maximizes protection but also enhances efficiency in packing and unpacking, reducing the risk of damage during these processes.

Over the past decade, technology integration into packaging has also transformed how we monitor and protect shipments. Tip-N-Tell indicators are just one method of protection. Advanced tracking devices that monitor temperature, humidity, and even atmospheric pressure are now commonly used to ensure the environmental conditions remain within safe limits throughout the journey.

This evolution is a testament to the packaging industry's responsiveness to the challenges posed by the transportation of increasingly sophisticated and sensitive equipment. The shift from rudimentary materials and methods to advanced, specialized solutions reflects both technological advancements and a deeper understanding of the logistical challenges involved in machinery transport.

Types of Packaging Techniques

When it comes to packaging heavy machinery for shipping or storage, crating and packaging providers employ a range of techniques designed to protect the machinery from damage, corrosion, and other shipping hazards. These techniques ensure the machinery arrives at its destination in the same condition it left.

Here are some common packaging methods used:

Wooden Crates and Skids:

Custom-built wooden crates and skids are among the most traditional and effective methods for shipping heavy machinery. These are designed based on the dimensions and weight of the machinery, providing sturdy support during transit. Skids allow for easy loading and unloading with forklifts.

Vibration and Shock Protection:

To protect machinery from damage caused by vibration and shocks during transit, materials like foam inserts, rubber mats, and vibration-dampening pads are used. These materials absorb shocks and vibrations, keeping the machinery stable.

Corrosion Inhibitors:

Heavy machinery is susceptible to corrosion, especially during sea transit. To protect against this, providers use corrosion inhibitors like VCI (Volatile Corrosion Inhibitor) films, bags, and coatings. These materials form a protective layer on the metal surfaces of the machinery, preventing corrosion.

Shrink Wrapping:

Shrink wrapping involves covering the machinery with a plastic film, which is then heated to create a tight seal around the item. This technique protects the machinery from dust, moisture, and other environmental factors. It can be used in combination with other packaging methods for added protection.

Rigging and Blocking:

For extremely heavy or oversized machinery, rigging and blocking techniques are employed to secure the machinery within the shipping container or crate. This involves using ropes, chains, and braces to ensure that the machinery does not move during transit.

Moisture Control:

Desiccants and moisture barrier bags are used to control humidity levels within the packaging. This is crucial for preventing rust and corrosion, especially in long-haul or international shipments.

Custom Foam Inserts:

Foam inserts can be custom-made to fit around irregularly shaped machinery or parts. These inserts provide cushioning and keep the machinery firmly in place, preventing movement and potential damage.

Tip-N'-Tell Indicators:

To monitor and indicate mishandling during transit, Tip-N'-Tell indicators can be attached to the packaging. These devices provide visual evidence if the machinery has been dropped or tilted beyond a certain angle, which is useful for insurance claims and identifying mishandling.

Each heavy machinery item may require a unique combination of these techniques based on its size, weight, shape, and sensitivity. A professional crating and packaging provider will assess the specific needs of each piece of machinery to determine the best packaging strategy.

Navigating Shipping Regulations

Understanding shipping regulations is crucial for manufacturers to maintain efficiency and stay competitive. Navigating domestic shipping laws involves complying with federal, state, and local requirements, while international shipping adds the complexity of customs laws, import tariffs, and necessary documentation. We'll explore these regulations in detail, offering practical tips and strategies to help you avoid fines and delays, ensuring your shipments are compliant.

For manufacturers, understanding the intricacies of shipping regulations is not just about keeping operations running smoothly—it's about maintaining a competitive edge. As you manage the movement of your valuable machinery, whether domestically or internationally, it's important to have a solid grasp of the evolving regulatory environment.

In the logistics world, there are many regulations to follow and if you don’t fully understand the legal landscapes of domestic and export shipping scenarios, you may face hefty fines or delays for your machinery shipment.

Domestic Shipping

Domestic shipping within a country requires adherence to a set of federal and state laws that govern the transportation of goods. These laws can vary significantly from one state to another, affecting everything from the types of machinery that can be shipped to the methods and routes of transportation. For example, in the United States, the Department of Transportation (DOT) imposes regulations that affect the shipping of oversized loads, requiring special permits and escort vehicles in many cases.

Beyond federal and state regulations, local jurisdictions may have additional requirements that impact how machinery is packaged and transported. These might include restrictions on truck sizes, weight limits on roads, and even specific environmental stipulations designed to protect local ecosystems. It is essential for shippers to be familiar with these local ordinances to avoid costly delays and fines.

Export Shipping

When shipping machinery internationally, companies must navigate a complex web of customs and import/export laws. This involves not only understanding the regulatory requirements of the originating country but also those of the destination country. Each country has its own set of rules regarding tariffs, duties, and necessary documentation, which can include export licenses, bills of lading, and other customs declarations.

International trade agreements can also play a significant role in shaping shipping practices. These agreements may provide opportunities for reduced tariffs or streamlined customs procedures, but they also come with their own requirements and paperwork. For instance, machinery shipped from the United States to a country with which it has a free trade agreement, like Canada or Mexico, might qualify for preferential tariff treatment under the terms of the United States-Mexico-Canada Agreement (USMCA).

Utilizing Country Commercial Guides

A pivotal resource for anyone involved in export shipping is the Country Commercial Guide (CCG). Prepared by U.S. Embassies abroad, these guides are tailored to provide critical information about the customs and regulatory requirements of different countries. They serve as a comprehensive starting point for understanding the specific rules that will affect your shipments.

- Import Tariffs: CCGs detail the average tariff rates applied to various types of goods, including those in sectors most likely to be exported. This information is vital for budgeting and pricing your products competitively in foreign markets.

- Import Requirements and Documentations: These guides explain the necessary documentation required for both the U.S. exporter and the foreign importer. They provide insights into the paperwork needed to ensure that shipments comply with both U.S. export regulations and the import regulations of the destination country.

- Labeling and Marking Requirements: Understanding the labeling and marking requirements is crucial, as non-compliance can lead to delays, fines, or even the rejection of shipments at the border. CCGs offer an overview of these requirements and point to resources where you can obtain more detailed information. They also cover restrictive advertising practices and packaging and recycling laws that might affect how you prepare your machinery for shipment.

- Special Situations: Whether dealing with temporarily imported goods or navigating prohibitions and restrictions, CCGs provide guidance on how to handle these complex scenarios. They also include contact information for local customs authorities, which can be invaluable in resolving issues that arise during the shipping process.

- Standards and Testing: CCGs describe the general environment for standards and testing in the destination country, including the relevant authorities and requirements. They also discuss how these standards are published, helping you ensure that your machinery meets all necessary criteria before shipment.

ISPM 15

ISPM 15, or the International Standards for Phytosanitary Measures No. 15, is a critical regulation for anyone involved in international shipping. It was established to prevent the global spread of disease and insects that could negatively impact plants and ecosystems. These standards are particularly focused on wood packaging materials such as pallets, crates, and dunnages which are often reused and can carry pests over long distances.

The importance of ISPM 15 regulations in export shipping cannot be overstated. These regulations are designed to ensure that wood used in international shipping is properly treated to kill pests. The standard methods approved under ISPM 15 include heat treatment and fumigation with methyl bromide. Following these treatments, wood packaging must be marked with a specific seal that shows it has been treated according to these standards. This mark includes the IPPC (International Plant Protection Convention) symbol, the country code, the producer or treatment provider’s unique code, and a code indicating the type of treatment used.

However, obtaining this mark of compliance involves more than just following treatment protocols. Companies must be certified by an accredited agency that verifies their compliance with ISPM 15 standards. This certification process ensures that companies not only treat the wood but do so consistently and effectively.

Despite these stringent measures, there are instances where companies may misuse the compliance mark. Some might mark their products as compliant without undergoing proper auditing or regular checks. This can lead to significant issues if the packaging is inspected at an international port and found non-compliant. Not only can this result in delays while the goods are quarantined or returned, but it can also lead to hefty fines. These penalties are generally imposed on the exporter, not the packaging provider, making it essential for companies to verify the credentials and reputation of their packaging suppliers.

Ensuring compliance with ISPM 15 is not just about adhering to legal requirements—it's about safeguarding your business against potential delays, fines, and damage to your reputation. Partnering with a reputable and properly audited packaging company is crucial. It's the best way to ensure that your goods move smoothly and without disruption through international supply chains. This proactive step helps maintain the integrity of your logistics operations and protects global ecosystems, aligning your business practices with international standards and commitments to environmental responsibility.

Common Machinery Packaging Mistakes

When it comes to transporting heavy machinery, you don't want common packaging errors to put your equipment at risk. Discover strategies to prevent these critical packaging errors, ensuring your equipment's safety throughout its journey.

Imagine this: a specialized optics machine, vital for a customer’s manufacturing floor, arrives with damage due to poor packaging. The downtime needed to replace it not only halts production but also causes significant financial losses and operational delays. This situation highlights just how crucial proper machinery packaging is. Here are some on the common machinery package mistakes and how to address them.

Inadequate Protective Measures:

🚫Problem: Machinery often suffers from inadequate protection, leading to damage from shock, vibration, or pressure during transit.

✔️Solution: Use high-quality, durable cushioning materials that match the weight and fragility of the machinery. Employ custom-fitted foam inserts and shock-absorbing pads to ensure the equipment remains immobile and protected.

Choosing the Wrong Crate Size:

🚫Problem: Using a crate that is too small or too large can cause the machinery to shift, leading to potential damage.

✔️Solution: Opt for custom-built crates that are designed specifically for your machinery. Ensure there is enough room for adequate cushioning but not so much that the item can move around during transport.

Using Substandard Packing Materials:

🚫Problem: Lower quality materials may save money upfront but often lead to damages that cost more in the long run.

✔️Solution: Invest in high-grade, robust materials for crating and cushioning. Quality materials not only protect better but also withstand the rigors of handling and shipping.

Failing to Protect Against Moisture:

🚫Problem: Moisture can lead to rust and other corrosive damage, especially when machinery is shipped over long distances or stored for extended periods.

✔️Solution: Incorporate moisture barriers such as vapor barrier bags and use desiccants within the packaging. Ensure crates are sealed properly to prevent any moisture ingress.

Inadequate Labeling:

🚫Problem: Improper labeling can result in mishandling, which may cause damage during loading, unloading, and transit.

✔️Solution: Clearly label all sides of the crate with handling instructions, weight specifications, and details of the contents. Use international symbols for handling fragile equipment and ensure labels are visible and easy to read.

Neglecting Insurance Coverage:

🚫Problem: Failing to insure your shipment can lead to significant financial losses if the machinery is damaged or lost.

✔️Solution: Always secure comprehensive insurance for your shipments. Ensure the coverage is adequate for the full value of the machinery and includes all potential risks during transit.

Preparing your Machinery for Packaging Success

Properly preparing machinery for packaging is essential to ensure it arrives at its destination in top condition. Manufacturers can take several key steps to facilitate a smoother packaging process and enhance the safety and security of their equipment during transit.

Proper preparation of machinery before packaging is crucial to ensure it arrives at its destination in the best possible condition. Manufacturers can take several steps to prepare their machinery, which not only facilitates a smoother packaging process but also enhances the safety and security of the equipment during transit.

- Conduct Pre-Shipment Testing:

If possible, conduct pre-shipment testing on any electronic or mechanical components to ensure they are fully functional before shipping. This step verifies that all parts are in working order and can help identify potential issues that might arise during transport.

- Clean And Inspect The Machinery:

Before packaging, thoroughly clean and inspect the machinery. Remove any dust, debris, coolant, or residues that might cause damage or corrosion during shipping. This step is also important for identifying any pre-existing issues that might be exacerbated during transit. Documenting the machinery’s condition can be useful for insurance and quality control purposes.

- Disassemble Parts When Applicable: Disassembling larger machines into manageable parts can reduce the risk of damage as each component can be individually wrapped and cushioned. It also makes handling easier and can sometimes reduce shipping costs due to more compact packaging. Be sure to label each part and provide assembly instructions

- Secure Loose Components: Any moving parts should be securely fastened to prevent them from moving during transit. Use cable ties, shrink wrap, or bands to keep components in place. Securing these parts not only prevents damage but also minimizes the chance of losing small, essential items.

-

Utilize Custom Crating and Packaging Services: A professional crating provider can be invaluable in this process. They can design and build custom crates that fit the machinery perfectly, considering factors like weight distribution, shock absorption, and moisture protection. Custom crates ensure that the machinery is snugly fitted within its container, minimizing movement and the potential for transit damage. They will also use appropriate protective materials, such as foam padding, bubble wrap, or vibration-dampening materials, around each part of the machinery. These materials should accommodate the weight and sensitivity of the components they are protecting.

- Ensure Proper Labeling and Documentation: Ensure that all parts and crates are correctly labeled with handling instructions, weight details, and any other necessary information. Professional craters can provide labels that meet international shipping standards and help with the documentation required for customs and insurance.

- Collaborate with Logistics Experts:

Working closely with your crating provider and logistics experts can streamline the entire shipping process. They can advise on the best routes, packaging methods, and compliance with international shipping regulations, making the process more efficient and less prone to errors.

Download our Free Infographic

Download our free infographic on how to prepare your machinery for packaging success.

The Integral Role of Rigging, Transport, and Storage

Shipping machinery often involves additional services such as rigging, transportation, and storage, which frequently overlap due to the project's scope. Discover how these integrated solutions can streamline and enhance your next machinery shipment.

When you're gearing up to ship heavy machinery, one of the key decisions is whether you want to handle or outsource the rigging and transportation of the machinery. Both options have their merits, and it’s vital to consider whether you can manage this part yourself.

Rigging heavy machinery often requires slings, straps, skates, forklifts, and in some cases, cranes. If you choose to outsource this task, a team of expert riggers will not only handle the heavy lifting but will also plan the most efficient routes to minimize disruptions within your facility. This expert handling can be essential to avoid any damage to both the machinery and the infrastructure of your facility.

Once the machinery has been rigged out of the facility, the next step is transportation. This phase connects the initial location to an offsite packaging facility. Professional transportation services focus on hauling oversized loads and delicate equipment that require specialized handling. They ensure that the machinery reaches its next destination—whether it's a few miles away or across state lines—in the exact condition it was in when it left the previous facility.

Warehousing plays a vital role here if there are any delays in the shipping schedule and there is a need for temporary storage before the machinery can be shipped to its final destination. A secure warehouse facility provides a controlled environment to store machinery safely, protecting it from environmental elements and potential security threats. It is especially beneficial in managing logistics efficiently when coordinating between multiple suppliers and shipment schedules.

Choosing a crating provider that also offers comprehensive services such as rigging, transportation, and warehousing can significantly streamline the crating and packaging process. By dealing with a single provider, businesses can save considerable time and resources. Coordination becomes simpler, risks of damage are minimized due to reduced handling, and overall costs can be significantly lower compared to hiring multiple vendors for different stages of the process.

Sector-specific Benefits of Expert Crating and Packaging

Explore how specialized crating and packaging can benefit various sectors, from manufacturing facilities to food and beverage companies, and optics to machinery dealers.

Every industry comes with its unique demands and nuances, and expert crating and packaging solutions are designed to meet these specific needs. By understanding the intricacies of each sector, tailored crating and packaging provide several key advantages that enhance operational efficiency, product safety, and overall customer satisfaction.

Here’s how tailored crating and packaging can benefit different sectors:

Circuit Board Producers

Circuit boards are the heart of many modern devices and require meticulous handling. Expert crating for these components includes the use of anti-static packaging materials that prevent electrostatic discharge, which can be fatal to electronic components. Custom-designed enclosures with foam inserts specifically molded to each board ensure that these delicate items remain secure and immobile throughout their journey.

Machine Shops

In machine shops where heavy and often irregularly shaped parts are the norm, specialized crating solutions are a must. Durable crates equipped with custom supports and padding protect each part from shocks and vibrations during transport. This not only safeguards the machinery but also preserves the precision with which they are machined.

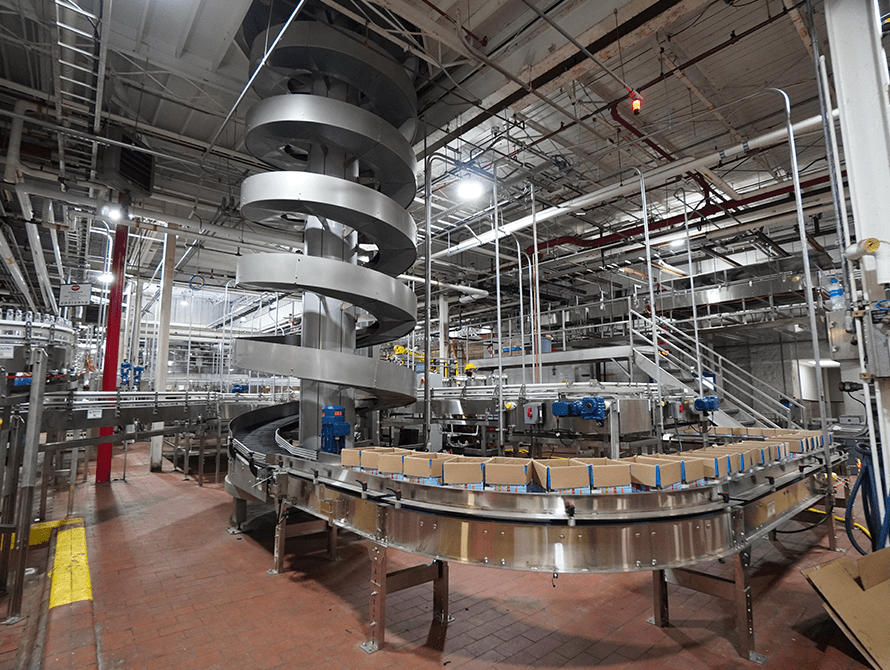

Food and Beverage

When shipping new equipment or relocating old conveyor lines within the food and beverage industry, proper packaging is paramount to prevent mechanical issues upon arrival. Conveyor systems require secure crating that stabilizes all components—especially the belts. Adequate support and cushioning must be employed to ensure that belts remain aligned and intact, avoiding any mishaps like a belt dislodging during transit. This kind of packaging ensures that the machinery can be immediately operational upon installation, reducing downtime and potential frustration.

Optics and Photonics

Equipment in the optics and photonics sector is highly susceptible to alignment issues if mishandled. Packaging for these items typically involves rigid containers fitted with custom foam that conform to the exact shape of each component. At Boulter, we use our floating base style crates for these since they are a foam-lined "crate within a crate" that absorbs the shocks of transit.

Machinery Dealers

Dealers who handle a wide array of machinery need versatile crating solutions that can accommodate different sizes and weights, ensuring that each piece of equipment is well-protected. Customized crating options allow dealers to safely ship machinery to customers or between dealerships, maintaining the equipment's integrity and operational readiness upon delivery.

Selecting the Right Logistics Partners

Choosing the right logistics partner can significantly simplify your machinery shipment process. By selecting a provider that offers comprehensive services—from rigging and crating to warehousing—you can streamline coordination, save time, and reduce costs.

Opting for a provider that handles everything from rigging to crating to warehousing can save you a headache and a half. It’s about slicing through the chaos of coordinating multiple vendors and ensuring everyone is on the same page, which in turn saves time and money.

Communication and reliability are key here. It’s about having that peace of mind, knowing your machinery is in good hands at every turn. Also, consider providers with strong networks in logistics services. These connections can streamline everything from quicker transit times to smoother customs clearance, ensuring your machinery reaches its destination without any snags.

Aim for the complete package: comprehensive services, certifications, and a reputation for reliability and transparency. That way, you safeguard your high-value assets, keeping your operations running smoothly and your reputation intact.

Your Crating and Shipping Questions Answered

This FAQ section addresses common questions about crating and shipping machinery, ensuring you have all the information you need for a smooth and successful process. These insights will help you navigate the complexities of machinery logistics with confidence and ease.

-

To ensure your shipment complies with ISPM 15 regulations, it's crucial to choose a reputable crating provider. These providers are regularly inspected to verify that they use appropriately treated materials and follow all regulatory requirements. It's also wise to have clauses in contracts with foreign suppliers that hold the exporter responsible for any costs incurred at customs if their wood packaging materials fail to meet the necessary standards.

-

When selecting a warehousing solution for your machinery, prioritize facilities that are secure, temperature-controlled, and moisture-free to prevent any damage to both the crates and the machinery inside. An ideal scenario is a warehouse that's connected to your crating provider’s facility, which simplifies the logistics of moving items in and out.

-

Absolutely! A crating provider can facilitate the documentation process, making it much smoother for you. This support typically includes preparing and handling essential documents such as export declarations, bills of lading, and customs forms. They often have established relationships with freight companies, insurance brokers, and customs agents to further streamline the export process.

-

The turnaround time for custom crates varies based on the type and size of machinery, as well as the destination.

For example, a large 60,000 lb. optics machine will typically take us one day to pick up, two days to build a crate, and two days to pack. Factors such as the materials used and the complexity of the packaging requirements will influence the timeline.

-

Oversized or irregularly shaped machinery requires specialized attention to ensure it is transported safely. Custom crating involves designing and building crates that exactly fit the dimensions and weight of the machinery. Additional supports might be used to secure the equipment within the crate, and high-grade cushioning materials are employed to protect sensitive components during transit. This meticulous process ensures that each piece, no matter its size or shape, is shielded from potential transport hazards.

Partner with Boulter for Unmatched Expertise

If you’re looking for a dependable crating and packaging provider, look no further than Boulter. As a trusted industry leader, we pride ourselves on offering top-notch custom crating and packaging solutions tailored to your specific needs.

You tell Boulter where your product's going, when it needs to be there, how it needs to get there and I let them manage the details."

Boulter is your go-to choice for custom crating solutions, offering more than just expertly designed crates for any type of machinery. As a full-service provider, Boulter simplifies your supply chain with integrated rigging, transportation, and warehousing solutions, enhancing efficiency and reducing coordination hassle. With our skilled team and comprehensive approach, we ensure your valuable equipment is securely handled and delivered on time, while our secure, climate-controlled warehousing options facilitate seamless transitions from storage to shipment. Choose Boulter for a streamlined process that protects your assets and bolsters your operations from start to finish.

Ready to Start Your Project? Schedule a Call with Our Crating Expert!

Now that you have gained a solid understanding of machinery crating and shipping best practices, you may be eager to kickstart your project with the help of a crating expert. We are here to provide you with valuable insights and guidance tailored to your specific rigging needs.

- Discuss your unique project needs with our crating expert

- Receive valuable insights to help your project succeed

- Save time and resources