In recent years DIY projects have become all the rage. From home improvement to auto repair, individuals are combing the internet to find the best ways to save time and money on tasks that once were left to the professionals. If you're looking to save time and money on your next rigging project, self-installation may sound like the perfect solution. But before you start trying to install your own equipment, there are a few factors to consider.

Tooling

Tooling

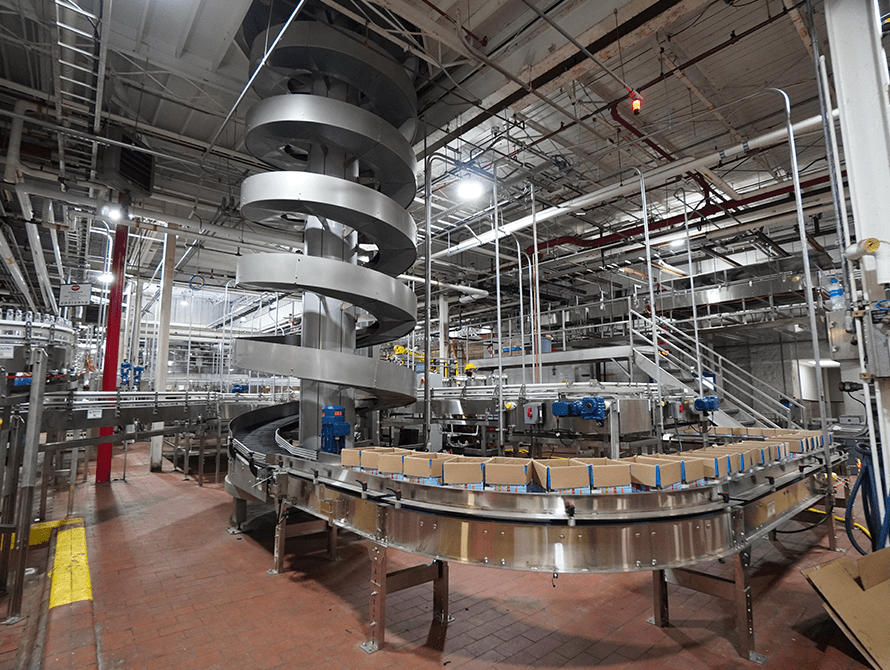

Before embarking on any installation project, it is crucial to consider whether you have the necessary tools and equipment to complete the job safely and effectively. While you may know your equipment and workspace best, attempting to self-install without the proper tools can result in costly mistakes and even pose a risk to your safety. The type of tools required will depend on the scope of the project, but it is essential to have access to a range of equipment, including slings, skates, jacks, heal bars, porta powers, blocks, forklifts, and cranes, to name a few. These tools can be used to lift, move, and position equipment, ensuring that it is installed correctly and securely.

It is also important to ensure that the tools and equipment are in good working condition and are appropriate for the specific job. Faulty or outdated equipment can result in lengthy downtime or even injury.

Equipment and Access Points

When it comes to industrial machinery, there are several challenges to consider. The size, weight, and cost of the equipment require careful planning and a wide range of tools. However, one crucial aspect that often gets overlooked is the access points. It is essential to measure the machinery accurately in relation to the access door to avoid any complications. If the equipment doesn't fit through the designated space, it can lead to unexpected delays and additional expenses. In some cases, modifications may even be necessary to accommodate the machinery, either to the equipment itself or the building. To ensure a smooth and successful relocation process, it is highly recommended to have a team of experienced professionals who can evaluate the situation and plan accordingly. They will help you navigate through these challenges effortlessly, ensuring that your project stays on track.

Experience

Experience is key when it comes to managing installations. Even the simplest of projects can quickly become complicated due to inclement weather conditions or unforeseen issues such as a small crack in the floor. To ensure a successful installation, individuals should possess the knowledge and resources necessary to manage these types of uncertainties effectively. This includes having knowledge of the equipment being installed, as well as a deep understanding of the installation process itself. Being able to quickly identify and address any issues that may arise during the installation process can help avoid costly mistakes and minimize downtime, ensuring that your business can continue to operate efficiently.

Safety

Safety is paramount. The most crucial detail that should always be addressed is if you can perform this installation safely—and if it’s worth doing in the first place. As recent as of 2020, OSHA reported that 4,764 workers died on the job— with transportation and material moving occupations and construction and extraction occupations accounting for nearly half of all fatal occupational injuries. Although exposure to these risks won’t always result in injury, ongoing safety training and knowledge of the installation process will help to prevent workplace accidents.

Conclusion

Self-installations can be an excellent way to save valuable time and money, but only if you have the appropriate resources and skills. Before deciding to DIY your next rigging job, it's important to consider a variety of factors, such as your own experience level, the complexity of the equipment involved, and the availability of necessary tools and materials. By taking these factors into account, you can make an informed decision that will help you achieve the results you want while avoiding potential setbacks and complications.

Of course, not everyone has the time, resources, or expertise required for a successful DIY installation. In such cases, it may be wise to consider professional installation services instead. Boulter is proud to offer top-notch installation services, with OSHA-trained crews who use only the best equipment and techniques. By working with us, you can rest assured that your installation will be completed safely and efficiently, with the highest levels of professionalism and attention to detail. So if you're ready to take your project to the next level, contact us today to learn more about our installation services and how we can help you achieve your goals.

Tooling

Tooling