Rebuild or Replace: The Best Option for your Conveyor System

For many manufacturers, conveyor systems are the backbone of their operations. Since their inception, they have helped alleviate the stresses of inefficient workflows and high labor-related costs. Therefore, when conveyor issues occur, they can have detrimental effects on productivity, and deciding whether to modify or replace isn’t always a cut and dry answer.

Here are a few factors to consider when making your decision:

Damage

Normal wear and tear issues typically can be fixed through quick repairs on the areas of concern. It’s when systems have extensive damage where total replacements are a more cost-effective option.

Types of conveyor issues include mistracking, belt slippage, seized rollers, belt tears, and blockages. The severity of these issues will determine whether your system needs minor work or a complete overhaul.

Mistracking

Conveyor belts are designed to follow a specific track. When the belt shifts off path, mistracking occurs and can cause system and product damage.

Belt slippage

Conveyor belts require a proper balance of load tension. When tension is uneven the belt can slip and can cause a domino effect of other issues including material spillage, blockages, and damage to the motor.

Seized rollers

Most conveyor rollers are manufactured using metallic-type products, like steel. These materials are ideal because of their durability but pose serious issues when they malfunction. Specifically, seized rollers can develop sharp edges resulting in mistracking, unsafe working conditions, and potential product damage.

Belt tears

Belt tears and seam rips are caused by heavy or improper loading and overuse. In some operations, they’re inevitable due to the nature of the product on the line. For example, systems running materials like coal or glass will have more belt perforations and should plan to implement a preventative maintenance program to address them.

Blockages

Between belt tears and incorrect item placement, blockages are common issues for conveyor systems. If not addressed in a timely fashion, however, this can lead to pileups and delays in production.

Age

Thanks to technological advancements and proactive maintenance, conveyor systems can run for several years without major issues. And in many cases, simple repairs to the existing equipment will keep operations running. A total system replacement should be considered when outdated technology slows productivity.

Since older equipment requires specialized parts that aren't always easily accessible and are often more expensive, these systems tend to be harder to service.

Timing

Full system installations take longer than modifications to the existing structure. They require removal of the existing line and delivery and setup of the new system.

If timing isn't an issue, full replacements may benefit your overall business strategy. Most contractors will accommodate your production schedule by working on evenings, weekends, or when production is slow to minimize downtime.

Previous repairs

Even conveyor equipment that’s been properly maintained will eventually fail. A good indicator that it may be time for an upgrade is when the system has undergone the same repair multiple times. Consistently patching these areas can lead to unusable equipment and unsafe working conditions.

Pricing

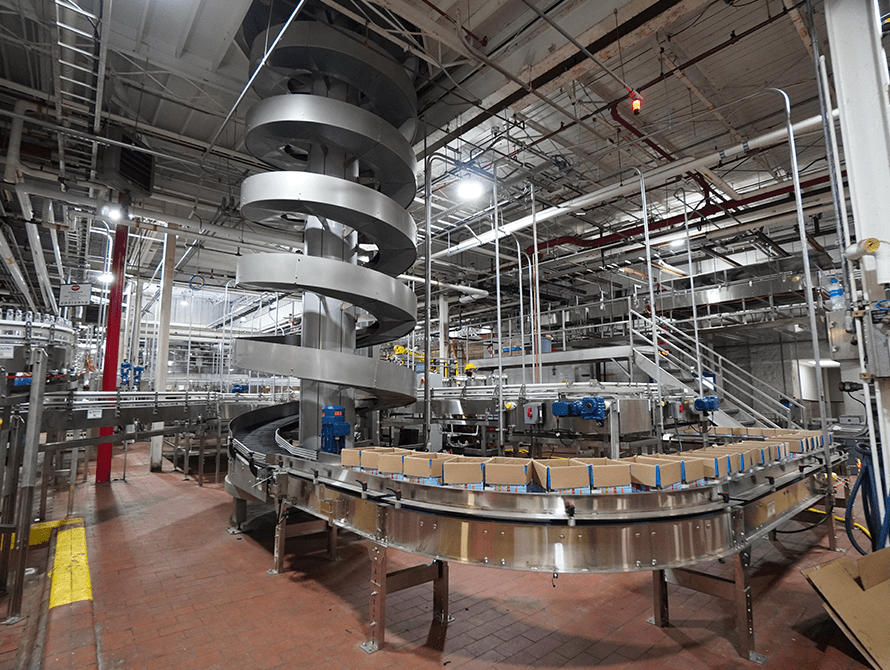

Price will depend on the types of conveyor systems and the material it handles. Most food and beverage plants have complex setups with multiple lines, robotics, spiralizers, and bottling machines, while warehousing material handling may have a minimal layout. Full replacements for more intricate systems tend to be more expensive and time-consuming.

Conclusion

Deciding on what conveyor option is best for your organization will depend on several factors. Whether you choose to rebuild or replace, using a trusted contractor with extensive knowledge of conveyor mechanics will ensure a smooth process from start to finish.

Boulter works closely with many food and beverage and manufacturing facilities on production line modifications and new system installs. Our expert rigging services and industrial maintenance support will help streamline your operations and increase plant efficiency. Schedule a meeting today with our conveyor system expert for a free, no-obligation quote.

Brittany joined the Boulter team in 2017, following her experiences in the entertainment and healthcare sectors. In her role as Marketing Manager, she oversees all aspects of Boulter's brand management and digital marketing initiatives. However, her passion extends beyond these responsibilities. Brittany is an advocate for encouraging younger generations to explore rewarding career opportunities in the trades, addressing the critical issue of labor shortage.