What comes to mind when you hear the term "rigging"? Some may think of ships hoisting sails, while others might envision cranes lifting heavy machinery. When people ask us, "What is rigging?" we always like to respond with a touch of humor, saying, "Remember that 'I pick things up and set them down' commercial?" While it's a lighthearted way to begin the conversation, rigging is, in reality, an intricate and critical process that plays a significant role in various industries, particularly in the industrial and construction sectors.

What is Rigging, Anyway?

To put it simply, rigging involves the use of specialized tools to lift, move, or relocate equipment. While it may be tempting to view rigging as just 'lifting stuff,' the definition is actually much broader. At its core, rigging is an intricate process that requires precise planning, expert skills, and specialized equipment to ensure the safe and effective movement or positioning of various loads. Whether you're lifting a massive steel beam into place or moving a delicate piece of machinery with sheer inches through a door, rigging is often the unsung hero that makes it all possible.

Rigging in Sailing

Interestingly, the concept of rigging is not limited to the industrial sphere. It can also be defined as the art of using ropes, cables, and chains to support a sailboat. This comparison is apt because, much like in industrial rigging, a sailboat involves the need for specialized knowledge and precise execution. A sailor needs to know which ropes to pull and when just as a rigger needs to know how to balance loads and operate lifting gear.

Rigging in Entertainment

It’s also worth mentioning that rigging has a different but equally important role in the entertainment industry. Here, rigging is generally divided into two categories: theatrical rigging and arena-style rigging. Theatrical rigging usually involves activities such as setting up backdrops, curtains, and lighting equipment in a controlled environment like a theatre. Arena-style rigging, on the other hand, is often used in larger venues like stadiums and involves much heavier loads. Despite the differences, both types require the same level of expertise and care to ensure that shows go off without a hitch—literally.

Industrial Rigging

In the industrial and construction sectors, rigging is vital for several reasons:

-

Safety: Improper rigging can be disastrous, leading to accidents, damage, and even loss of life. Hence, it's crucial to have trained professionals on board.

-

Efficiency: Expert rigging can save time and resources, allowing for smoother operations and quicker project completion.

-

Versatility: The ability to move various types of loads makes rigging indispensable in these sectors, where the equipment can range from delicate machinery to massive steel beams.

Rigging Equipment

Industrial rigging equipment is a crucial component of any rigging operation. The wide range of equipment available allows riggers to effectively and safely lift, relocate, and move equipment of various sizes and weights. These tools are essential for ensuring smooth operations and minimizing the risk of accidents or damage.

Shackles are commonly used in rigging to connect and secure lifting slings to the load. They come in various sizes and configurations to accommodate different load capacities and attachment requirements. Slings, on the other hand, are used to suspend and support the load during lifting operations. They can be made of wire rope, chain, or synthetic materials, depending on the specific requirements of the job.

Turnbuckles are another important piece of rigging equipment. They are used to adjust the tension and length of wire ropes or cables, ensuring that the load is properly balanced and secure. This is crucial for maintaining stability and preventing any shifting or swinging during lifting or relocation.

Wire ropes and chains are the primary means of lifting and supporting heavy loads in industrial rigging. Wire ropes are composed of multiple strands of wire twisted together to form a strong and flexible lifting medium. They are highly resistant to abrasion, corrosion, and fatigue, making them ideal for heavy-duty rigging applications. Chains, on the other hand, are known for their exceptional strength and durability. They are often used in applications where high load capacities and resistance to wear and tear are required.

Chain hoists are commonly used in industrial rigging to lift and lower heavy loads. They consist of a chain and a pulley system that allows for controlled lifting and lowering operations. Porta powers, jacks, and skates are additional tools that assist in the rigging process. Porta powers are hydraulic systems used to generate a controlled force for lifting or pushing heavy loads. Jacks, on the other hand, are mechanical devices that use a screw mechanism to lift heavy loads. Skates are specialized equipment that allows for easy movement of heavy loads, particularly on smooth surfaces.

When installing a CNC machine, rigging professionals may utilize a combination of these tools. Forklifts are used to lift the machine, while a skate system is employed to guide the front and ensure precise positioning. Heel bars and lifting jacks are then used to set the machine in place, ensuring stability and accuracy.

The Importance of Skilled Professionals

Riggers are the backbone of any rigging operation. These highly trained individuals have the expertise to work with lifting equipment and determine the best course of action to transport objects to their desired locations. Rigging professionals carefully examine the size, weight, and balance point of each object before devising a plan that minimizes the risk of equipment damage.

Without proper knowledge of the equipment, process, and hand signals, a job can quickly become dangerous. That's why it's important for the rigging crew to adhere to the regulations set forth by the Occupational Safety and Health Administration (OSHA). OSHA ensures the safety of rigging equipment and operations by requiring qualified riggers to possess recognized degrees/certificates or extensive knowledge, training, and experience. These qualified riggers are able to solve problems related to rigging loads and mitigate the risks associated with rigging operations.

While it may be fun to simplify rigging as "picking things up and setting them down," it's clear that the process is much more intricate and nuanced. From its roles in the industrial and construction sectors to its application in sailing and entertainment, rigging is a complex and indispensable art and science. Next time you see a crane hoisting a beam into place or marvel at an elaborate stage setup at a concert, remember that rigging is the invisible force making it all happen.

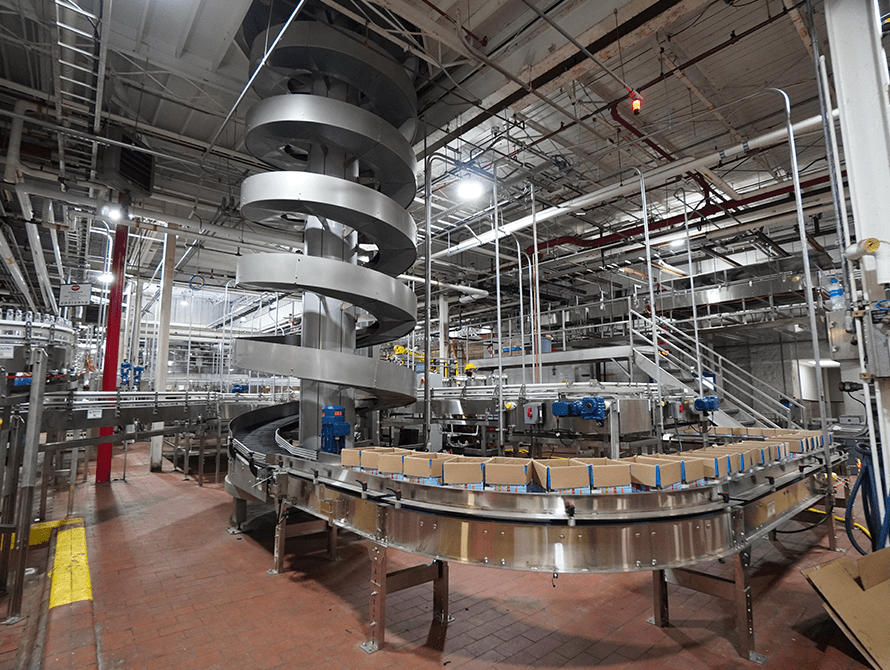

At Boulter, we take pride in our ability to provide comprehensive rigging services to a diverse range of industries. Whether it's manufacturing, food and beverage, retail, healthcare, education, or even the creative arts, our team has the expertise and experience to handle any rigging project that comes our way. We understand the importance of a successful rigging operation and are committed to providing the highest level of service and expertise.

To learn more about how we can assist with your next rigging project, schedule a Zoom meeting with me today. My calendar is available for direct booking, eliminating the hassle of back-and-forth communication.

Ryan joined the Boulter team in 2016 as a field employee before transitioning to Packaging Shop Supervisor and now Project Manager. With his diverse background in the field and the crating and packaging shop, he is well-equipped to handle the complexities and challenges that come with managing projects of varying scales and requirements.