An industrial maintenance program, also known as proactive or preventative maintenance, is performed when equipment is functioning as expected to reduce the likelihood of failure. When successfully implemented, these types of maintenance strategies will prolong equipment life, minimize downtime, and increase plant efficiency.

Reactive maintenance on the other hand is performed when equipment malfunctions. Since reactive maintenance requires no upfront costs or planning, this may seem more cost-effective but tends to be more expensive if used exclusively.

When looking at both strategies for your business, it’s important to consider the factors below.

Repairs

Reactive maintenance addresses issues as they arise rather than anticipating potential breakdowns. In this approach, equipment is only corrected when it’s run to failure. This can lead to higher repair costs or total replacements as spare parts may not be readily available.

When equipment is maintained in its optimal form, asset life and plant efficiency increase. During these routine maintenance checks, technicians can monitor operating conditions and determine how to improve the production process.

Downtime

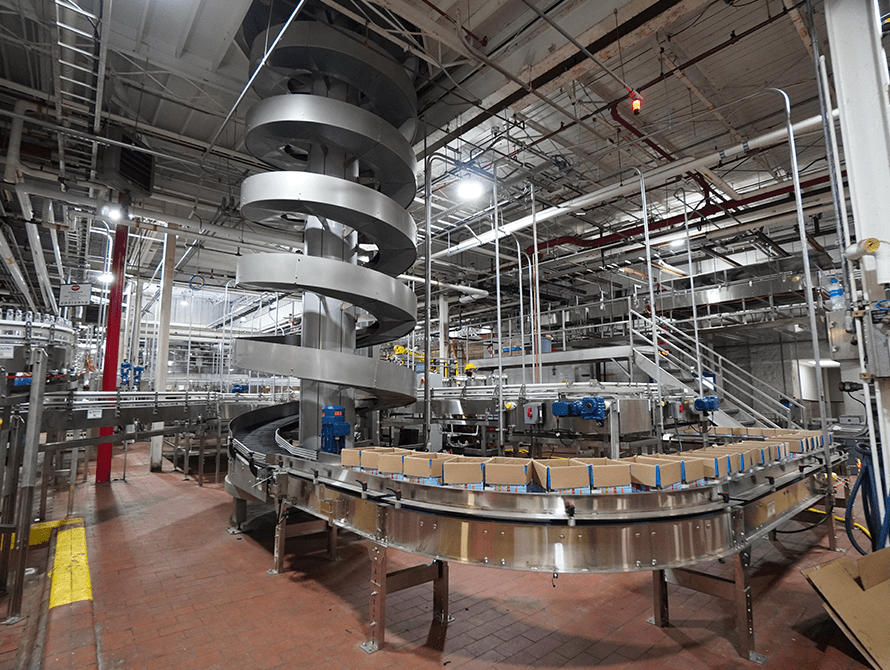

Any lapse in operations can impact productivity and profitability. That’s why it's critical to keep your equipment running and limit disruptions to operations. A preventative maintenance program will work to minimize the amount of unplanned downtime from equipment failure. This is successful when equipment undergoes regular inspections that are logged for future use. To further decrease downtime, this work can be performed during weekend or evening shifts when production is slow or through a scheduled plant shutdown.

Labor-Related Costs

Reactive maintenance and overtime often go hand and hand. Unexpected repairs are typically more time-consuming because they are harder to diagnose and spare parts aren’t always readily available. They are also prioritized over scheduled work leading to a greater sense of urgency and stressful working conditions for technicians. However, this isn’t always the case if reactive maintenance issues involve low-priority equipment that isn’t essential to operations. With planned maintenance, in-house technicians, contractors, or a combination of both, will work on a set schedule to avoid overtime or other high labor-related costs.

Safety

As previously mentioned, breakdown maintenance is more time-sensitive. The high-pressure working environment can cause technicians to take more risks to get the piece of equipment up and running again. This sense of urgency could also lead to inexperienced workers assisting with repairs.

Working with machinery without experience can be extremely dangerous. Just as an individual must meet qualifications before driving a car, factory machine work should only be performed by trained and knowledgeable operators. With scheduled work, the risk of injury is reduced as the maintenance team works on a flexible schedule while following the appropriate procedures and safety guidelines.

Conclusion

Reactive maintenance can play an important role in your strategy. This “fix it when it breaks” method can drive down costs when used on equipment that is older, cheaper to fix, or not essential to operations. It can also be more expensive and make operations harder to manage if used as the only form of maintenance.

Organizations that use a combined approach with preventative maintenance for overall operations and reactive for low-priority issues can save money, minimize downtime, and reduce production loss.

If you’re looking for industrial maintenance support, Boulter offers cost-effective maintenance services tailored to your specific business needs and time frame. We’ve successfully handled everything from total plant shutdowns to everyday maintenance. We will also work as support staff to your team so they can focus on the larger tasks at hand.

Contact our maintenance specialist today to discuss your project requirements.