Revamp Your Plant Management Game: The Power of Outsourced Maintenance

As a plant manager, you face immense pressure and endless tasks on a daily basis. Your primary objective is to ensure your plant operates efficiently and achieves production goals, all the while managing expenses, maintaining quality, managing your team, and prioritizing safety. No big deal, right?

We get it - it can be overwhelming and exhausting, with the demands often outweighing the available resources. But the good news is there is a solution: hiring an outsourced maintenance contractor. By bringing in an external partner to supplement your maintenance team, you can not only alleviate the stress but also reap the rewards of long-term savings. Let us take a closer look at the benefits of this approach.

Production Targets

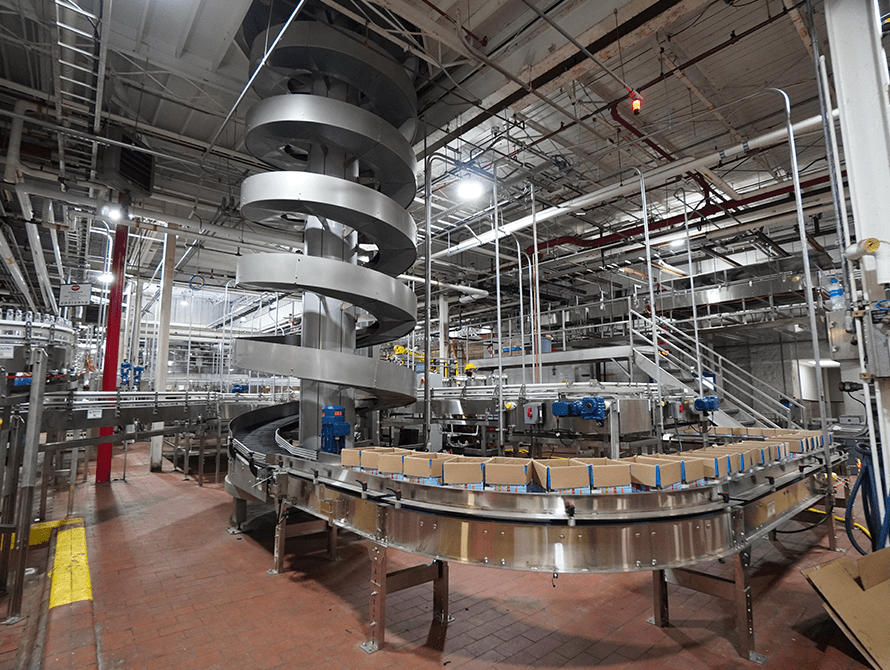

Let's talk about those production goals. We understand that they may often feel out of reach, like the elusive stars you are constantly reaching for. But by partnering with an outsourced maintenance contractor that specializes in preventative maintenance, you can ensure that your machinery is always in optimal condition, cashing in on those equipment savings.

An outsourced maintenance team will act as an extension of your existing maintenance department, providing the necessary expertise and resources to ensure the smooth operation of your plant. With their specialized knowledge and experience in preventative plant maintenance, they can proactively identify and address any potential issues before they escalate into costly breakdowns or disruptions in production.

"This means less downtime, improved efficiency, and ultimately, a greater chance of meeting those production targets."

Controlling Costs

Balancing the financial aspect of plant operations can be tricky, especially when it comes to implementing a maintenance plan. By using a contractor to supplement your maintenance tasks you can avoid incurring the high overhead costs associated with training and managing an in-house maintenance team. Instead, when you rely on the expertise and resources of a reputable and skilled maintenance partner, you're provided with cost-effective solutions tailored to your specific needs.

An outsourced maintenance contractor can provide flexible staffing solutions to meet your fluctuating maintenance demands. Whether you need additional support during peak periods or specialized expertise for specific projects, they can quickly adapt to your changing needs. This flexibility allows you to scale your maintenance operations effectively, ensuring that you have the right resources in place at the right time.

Maintaining Quality

You can’t overlook a crucial factor of plant operations which is maintaining quality equipment and ensuring quality output. Because when it comes to maintaining quality, relying solely on your in-house team may not always be sufficient. They may be overwhelmed with their regular responsibilities, making it difficult to dedicate the time and attention needed for thorough equipment maintenance. When partnering with an outsourced maintenance contractor, you can have peace of mind knowing that a team of experts is solely focused on maintaining the quality of your plant's assets.

Outsourced maintenance contractors have the expertise and experience to identify any potential issues or areas for improvement in your equipment. They can conduct regular inspections, perform routine maintenance tasks, and address any issues promptly to ensure that your equipment is always operating at its best. By having this second pair of hands and eyes, you can minimize the risk of equipment breakdowns, production delays, and costly repairs.

Additionally, these skilled experts are up to date with the latest industry standards and best practices. They have worked with various plants and industries, giving them a broader perspective and a wealth of knowledge to draw from. This enables them to implement innovative maintenance techniques and recommend improvements to enhance the overall quality of your plant's assets. At the end of the day, you want to be sure you're not only provided with extra support but that your equipment is maintained to the highest quality standards. Their specialized skills, knowledge, and experience enable them to identify and address any potential issues promptly, ensuring that your plant operates at its best.

Managing People

Managing the human element can be almost as challenging as the technical aspects of plant management. As a plant manager, you are responsible for overseeing a team of employees, ensuring they are motivated, productive, and working together efficiently. This can be a complex task, especially when dealing with different personalities, skill levels, and work styles.

With an outsourced maintenance contractor, you can alleviate some of the burdens associated with managing a team of employees. The company's dedicated professionals will work closely with your in-house team, overseeing equipment performance and ensuring that all maintenance activities are coordinated and prioritized.

By offloading the responsibilities related to managing a team, you can redirect your attention and energy to more strategic matters that require your expertise. This might include developing long-term growth strategies, enhancing operational efficiency, or implementing continuous improvement initiatives. With the support of the outsourced maintenance contractor, you can focus on driving innovation and achieving your plant's goals while still ensuring a well-maintained and productive environment.

Outsourcing maintenance can also bring a fresh perspective and additional training to your team. These professionals have experience working with different plants and industries, allowing them to offer insights and recommendations based on their expertise. Their objective viewpoint can identify areas for improvement that may have been overlooked by your internal team, leading to significant cost savings and operational enhancements. They may also provide specialized training to your in-house team, equipping them with the skills and knowledge necessary to excel in their roles. With shadowing and on-the-job training that includes new techniques, best practices, and the latest industry standards, your team can be kept up to date with the latest advancements in maintenance practices.

Prioritizing Safety

Safety is paramount in any plant environment. A maintenance professional prioritizes safety by implementing proactive maintenance practices, conducting regular inspections, and addressing any potential hazards promptly. They will help you keep your equipment running smoothly and ensure the safety of your employees so you can create a secure work environment that minimizes risks and promotes productivity.

In addition to their regular maintenance tasks, your outsourced team can also play a crucial role in ensuring the safety of your plant by performing preventative maintenance work during scheduled shutdowns. This proactive approach helps minimize downtime and creates a secure work environment for your employees.

During these scheduled shutdowns, they will thoroughly inspect and maintain all equipment to identify any potential hazards or issues that could result in equipment failure. Addressing these concerns before they progress can minimize plant downtime and prevent accidents and injuries from occurring in the future.

Conclusion

By entrusting your maintenance needs to an outsourced contractor, you can free up valuable time and resources that can be redirected toward other critical aspects of your plant operations. This expands your maintenance capabilities, reduces costs, improves quality, streamlines operations, and enhances safety. With the burden of day-to-day maintenance tasks lifted you can focus on driving innovation, enhancing operational efficiency, and achieving long-term growth for your plant.

Jeff began his career as an Ironworker apprentice in 1998 before transitioning through the ranks to his current role as Project Manager in 2013. With a concept-to-execution approach and extensive knowledge of steel fabrication, rigging, and preventative maintenance programs, Jeff successfully oversees a range of projects while adhering to the customer’s deadline, budget, and scope of work.