When it comes to business finance, every dollar saved is a dollar earned. If maximizing efficiency and minimizing costs are at the forefront of your business strategy, you’ve landed on the right blog. Let’s explore how to fine-tune your supply chain to ensure that your machinery investments are managed with unmatched precision.

Efficient management of machinery investments is critical for maintaining competitiveness and ensuring smooth financial operations. That’s why working with a company that recognizes the financial significance of your machinery investments and positions itself as your strategic partner is especially important.

Warehousing

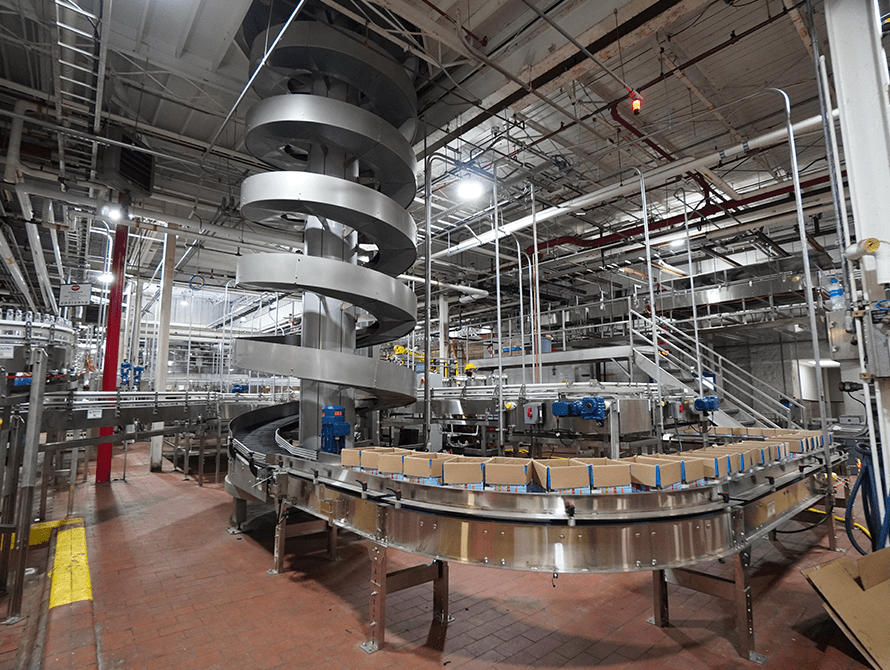

Supply chain disruptions can have profound financial implications for businesses and your reputation. As your financial ally, this partner will step in to smooth out any disruptions in your supply chain. From the moment your machinery arrives at their secure warehouse, meticulous attention will be paid to every detail. This company ensures peace of mind by coordinating deliveries and installations to align seamlessly with your operational schedule, minimizing downtime and maximizing cost savings.

Crating and Packaging

Machinery crating and packaging is more complicated than taking a package to the post office. Between the route to the equipment itself, not having a company that understands this can be the difference between a smooth delivery and one with damage and hefty fines. All this can hinder your supply chain and tarnish your reputation with customers. Working with a reputable custom crating and packaging provider, one that offers support services can ensure a smooth process for your entire project from start to finish.

Rigging

Selecting a rigging partner accustomed to the financial implications of your machinery investments is akin to choosing a strategic ally in your pursuit of operational excellence. This partner becomes instrumental in not just moving your machinery but in doing so in a way that aligns with your broader financial and operational goals. The expertise brought to the table in navigating the complexities of rigging ensures that every step in the process is executed with precision, minimizing potential disruptions and maximizing efficiency.

The value of a skilled rigging service is immeasurable when considering the potential cost savings and efficiency gains. A streamlined installation process ensures that your machinery is up and running as quickly as possible, reducing downtime and accelerating the timeline to productivity. This efficiency translates directly into cost savings, allowing your business to allocate resources more effectively elsewhere.

Preventative Maintenance

Machinery downtime is a direct hit to your bottom line. Whether you're grappling with staffing shortages or navigating tight project deadlines, working with a partner that offers preventative maintenance services will keep your machinery operating at peak efficiency. For example, suppose you need support one day a month during a scheduled shutdown. In that case, a preventative maintenance contractor can send a team of millwrights to adjust belts, run grease guns, adjust conveyor guides, replace worn parts, change motors, belts, or chains—anything your maintenance staff needs that they can’t get to with their day-to-day schedule.

An added benefit is when this partner offers line audits for facilities looking for a more comprehensive equipment review. In today’s environment, most maintenance teams are already short-staffed and may not have the resources available for an intensive line review. As a strategic partner, this company serves as additional support, reviewing your equipment and providing a detailed report of the findings. It’s a quick way to offer assistance when needed but not replace your maintenance team.

Minimizing downtime is paramount for maintaining productivity and profitability. That's why we've developed our Downtime Calculator. This tool allows you to quantify the financial impact of machinery downtime, providing a clear picture of how preventive maintenance can significantly enhance your bottom line. By inputting simple parameters about your operations, the calculator showcases potential savings, making it easier to justify investments in maintenance services.

Efficiently managing your machinery investments requires a partner who not only understands the technical aspects of your equipment but also the financial implications of downtime, damage, and delays. At Boulter, we transcend the role of mere service provider – we are your financial steward in pursuit of success. Witnessing our clients' financial growth is our pride, and we stand ready to support your financial journey. With our comprehensive suite of services, including warehousing, rigging, packaging and crating, and preventative maintenance, we ensure that your machinery investments yield maximum financial returns. Don't allow logistical challenges to erode your financial gains – entrust your machinery to Boulter.

William began working on a field crew in 1988. He transitioned through the ranks and became President in 1998. Since that time he has become CEO in 2006 with the successful transition from fourth to fifth generation of Boulters. He is a graduate of Alfred State College. William’s goal is to help Boulter excel with each project it undertakes.