For manufacturers, finding smart ways to cut costs without sacrificing efficiency is crucial. One of the best-kept secrets in achieving this balance is offsite warehousing. Whether you’re a small manufacturer looking to scale or an established company aiming to streamline operations, offsite warehousing offers a range of benefits that can significantly impact your bottom line. Discover how utilizing offsite storage solutions can lead to substantial savings, improve operational efficiency, and provide the flexibility needed to stay competitive in an ever-evolving market.

Understanding Your Challenges

We hear from our customers all the time that their biggest challenges are the lack of skilled labor and resources needed for their projects. These resources can range from specialized equipment to the space itself. Sometimes, the space needed before a project even starts can be a significant hurdle. This is where offsite warehousing comes into play.

How Offsite Warehousing Eases Project Management:

- Space Readiness: By securing offsite storage, you ensure that you have the necessary space to stage and organize your project before it begins.

- Resource Allocation: With offsite warehousing, you can efficiently manage your resources without the constraints of limited in-house space, allowing your team to focus on what they do best.

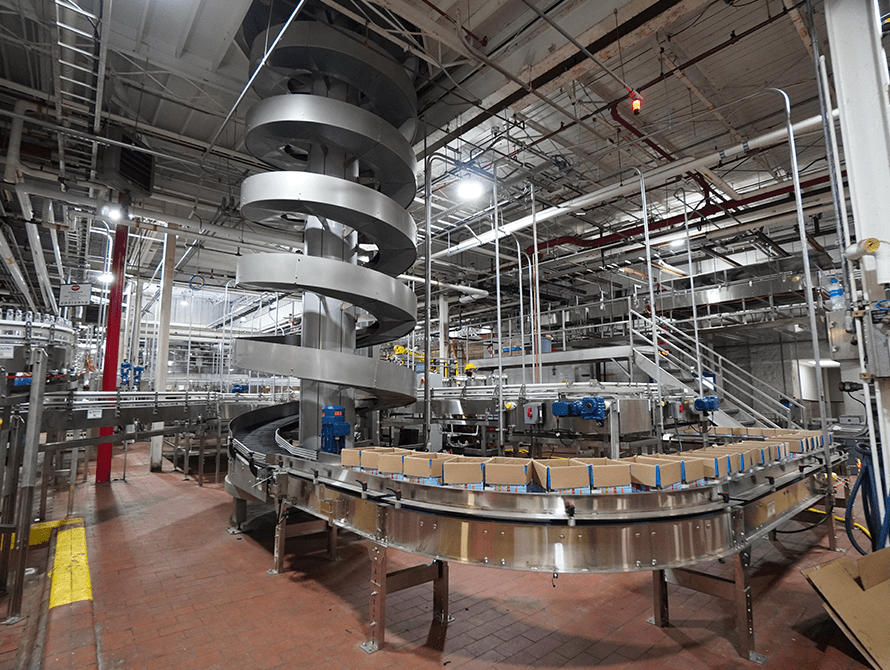

For manufacturers looking to optimize operations and expand capabilities, offsite warehousing can be a game changer. It offers much-needed space within existing facilities, freeing up valuable real estate for more critical tasks. This isn’t just about storing away seldom-used equipment; it’s about reimagining and reorganizing your workspace for maximum efficiency.

Benefits of Reconfiguring Production Areas:

- Enhanced Layouts: By moving non-essential equipment offsite, you can redesign your production areas to enhance operational flow and productivity.

- Increased Efficiency: A well-organized workspace leads to more efficient operations, helping your team work smarter, not harder.

.png?width=1200&height=300&name=CTA%20(4).png)

Flexibility to Scale with Market Demands

The dynamic nature of manufacturing demands flexibility, especially when scaling production up or down. Offsite warehousing provides a versatile solution, allowing manufacturers to adjust storage needs without hefty investments in physical assets. This adaptability is essential for responding swiftly and economically to market changes.

Advantages of Offsite Warehousing:

- Cost Savings: Outsourcing storage eliminates expenses tied to owning and maintaining warehouse spaces, such as rent, utilities, and maintenance.

- Reduced Administrative Burden: Freeing up capital and reducing the administrative tasks associated with property management allows you to focus more on core business activities.

What to Look for in an Offsite Warehouse

Selecting the right offsite warehouse is a critical decision. Key considerations include the facility's location, capacity, and security measures. Ensure the facility offers adequate space for growth and has stringent security protocols.

Important Features to Consider:

- Climate Control: Ensures your products are stored in optimal conditions.

- Security: Robust internal and external security measures to protect your assets.

- Proximity: Close proximity to your building or project site for convenience.

- Additional Services: Does the provider offer transportation, rigging, crating, and packaging services to streamline your processes?

Partnering with third-party warehousing experts offers more than just extra space. These providers bring specialized knowledge and facilities equipped to handle sensitive or high-value products. This expertise ensures your equipment and products are maintained under optimal conditions, minimizing the risk of damage and loss—a direct cost-saving for any manufacturer.

At Boulter, we’re ready to handle your warehousing requests. Whether you need internal climate-controlled storage for your optics machinery or outdoor yard space for a 75 ft. tall tank, we can support your needs.

.png?width=1200&height=300&name=CTA%20(4).png)