Subscribe via Email

Subscribe to our blog to get insights sent directly to your inbox.

-

Featured News

Lift & Move USA Ambassador

We're passionate advocates for the industry, dedicated to showcasing the awesome opportunities in skilled trades. Discover our role as a Lift & Move USA Workforce Ambassador, where we inspire the next generation to pursue rewarding careers in the trades.

-

The Ultimate Rigging Guide

What Is Rigging?

Looking for a comprehensive resource that will equip you with the knowledge and insights needed to conquer your next industrial project? Check out our ultimate rigging guide!

-

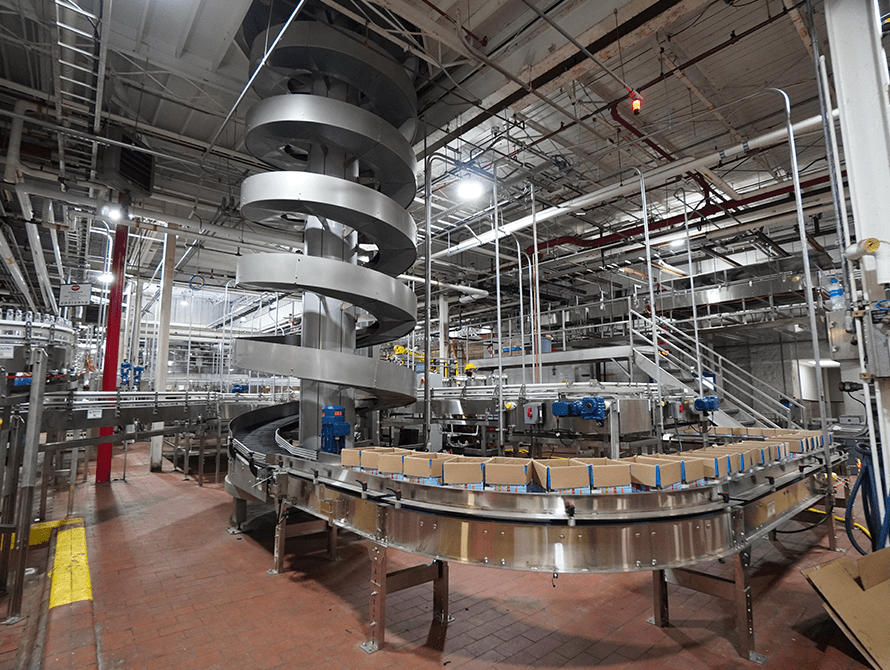

Genesee Brewery Case Study

Genesee Brewery Case Study

Discover how our manufacturing solutions help Genesee Brewery expand their operations and enhance plant efficiency.

- Case Studies

-

Industrial Crating Guide

Industrial Crating Guide

Machinery crating and shipping can be a complex process, but it doesn’t have to overwhelm you. Our comprehensive shipping guide is drawn from industry experts and is packed with tips and tricks to ensure your items reach their destination intact.

- Request A Quote