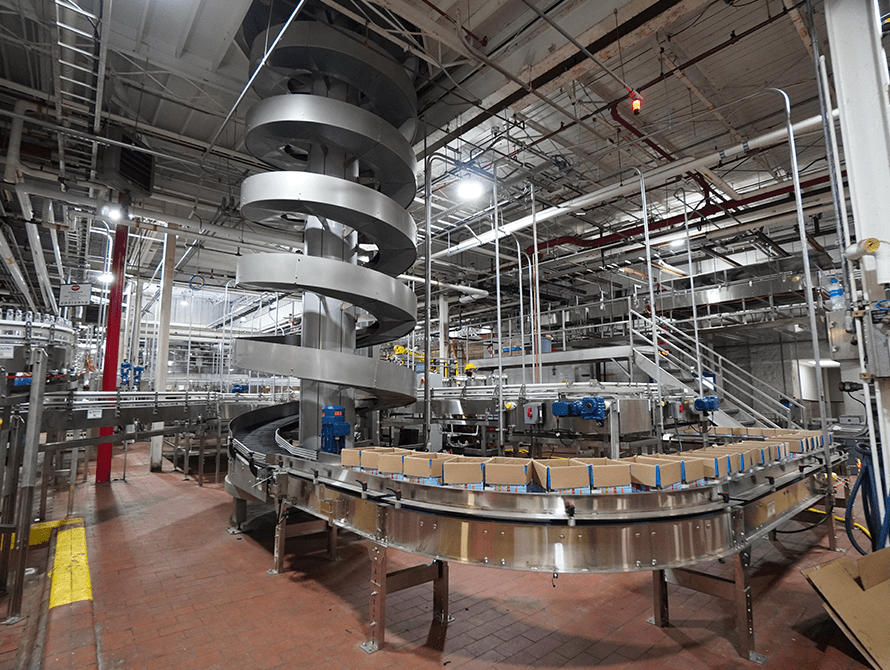

The Essential Role of Crating in Machinery Transport

Relocating machinery isn't like moving your grandmother's china. It's bulky, heavy, and let's face it, a lot more valuable than that delicate tea set. That's why crating plays such an important role in ensuring your equipment arrives at its destination unscathed. A well-crafted crate shields your machinery from moisture, dust, vibrations, dents, rust, and shocks, preventing the kinds of damage that could derail your entire operation.

When manufacturers invest in proper crating, they eliminate many of the headaches that go hand-in-hand with machinery transport. Worried about how your equipment will hold up during transit? A well-built crate has you covered. Concerned about costly downtime? Proper-built crates prevent delays.

Crates provide a protective barrier around the machinery, shielding it from external factors that could potentially cause damage. Think of it as armor for your machinery. They act as a cushion, absorbing shocks and vibrations that may occur during transportation. Crates also offer a level of security by preventing unauthorized access to the machinery. They can be designed with lockable mechanisms, ensuring that only authorized personnel can access the contents. This helps to protect valuable machinery from theft or tampering.

Another advantage of using a crate for your machinery is that it allows for easier handling and storage. They can be easily maneuvered using forklifts or other equipment that allows for efficient loading and unloading. Crates can also be stacked, optimizing storage space and reducing the risk of damage from improper stacking methods.

The weight, sensitivity, and destination of the machine will determine the types of packaging materials inside the crate. These materials can include:

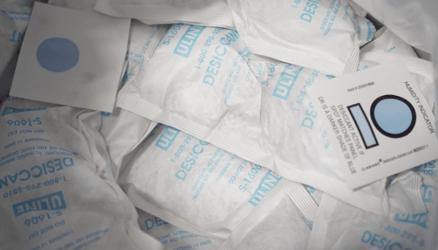

Desiccant

Desiccants are an essential component of storing, shipping, and preserving goods. These packets, usually filled with clay or silica gel, absorb moisture and humidity, thereby protecting their contents.

Barrier Bagging

Vapor barrier bags are necessary to guard products against damage from moisture, salt, or humidity. They are particularly crucial when transporting items by sea cargo, as the salt water can cause corrosion in electronics and metal gear.

Barrier bagging is a part of the final packing process before an item is placed in a crate. After all of the items are safely in the bag, a vacuum is used to extract the air and then the bag is sealed.

Shrink Wrap

If you're a boat owner, chances are you're familiar with shrink wrap as many marinas use it to prep boats for storage. It is also used in the packaging process because of its elasticity and durability. When heated, this pliable material creates an airtight seal making it an effective way to guard items shipped within the country.

Blocking and Bracing

When transporting goods, you want to ensure that they arrive undamaged. Though it is hoped that shipments are handled with the same caution as in the shop, this is not always the case. To guarantee safe delivery, additional packaging measures should be taken and the proper materials should be used. A variety of protective tools, such as wood braces, metal brackets, ratchet straps, and metal banding, help secure items in place.

Floating Bases

Floating bases are designed to absorb the shock and vibration of the freight. These can be built as part of the crate design or inserted within the crate as an additional cushioning measure for highly sensitive equipment. Bases within the crate typically include foam lining, risers, and a floating desk to ensure little movement during transit. From there, equipment is secured to the floating base with straps or banding further minimizing any impact.

Crates are designed with structural integrity in mind, using robust materials and reinforcement techniques. This prevents the machinery from being subjected to excessive forces or impacts that could lead to damage. This physical damage can be costly, cause significant shipping delays, and ruin your reputation with customers.

When it comes to machinery transport, meeting safety and compliance standards is crucial. Crating plays a significant role in ensuring that these standards are met. Crates are designed to comply with industry-specific regulations and requirements. They are engineered to provide adequate protection and support for the machinery, ensuring that it remains stable and secure throughout the transportation process.

By using crates that meet safety and compliance standards, manufacturers can avoid penalties or legal issues associated with non-compliance. This helps in maintaining a positive reputation and building trust with customers and regulatory authorities. Using compliant crates also demonstrates a commitment to safety and professionalism. It reassures customers that their machinery is being handled with care and in accordance with industry best practices.

While a sturdy, well-crafted crate is essential to protect your equipment during transit, choosing the right provider to build that crate is just as important. A reliable crating provider brings expertise and experience to the table, knowing exactly how to design and construct crates that meet the specific needs of your machinery. They understand that each piece of equipment is unique, requiring careful consideration of weight distribution, sensitivity to environmental factors, and more. With the right provider, your crate won’t just be a box—it will be a customized solution designed to shield your machinery from all the hazards of transportation.

The best providers also keep up with industry standards and regulations, ensuring that your crates are compliant with all requirements. This isn’t just about avoiding legal trouble; it’s about making sure your machinery arrives safely and without a hitch. When a provider understands the ins and outs of these standards, you can trust that your equipment is in good hands.

Communication is another critical aspect. The right provider will take the time to understand your specific concerns and needs, working closely with you to ensure the crate meets all your expectations. They won’t just build what they think you need—they’ll build what you know you need. This kind of partnership gives you peace of mind, knowing your valuable machinery is being handled with care and precision.

In the end, the right crating provider is more than just a contractor—they’re a partner in protecting your investment. When you choose a provider who knows their craft and values your input, you’re not just getting a crate. You’re getting a solution that ensures your machinery arrives safely, on time, and ready to get back to work.

Crating is more than just a protective measure—it's a critical part of the entire machinery transport process. When done right, crating safeguards your equipment from the many challenges it might encounter during its journey, from rough handling to environmental exposure. It’s about ensuring that every piece of machinery, regardless of size or complexity, is fully protected and secure. Proper crating minimizes the risk of damage, reduces downtime, and ultimately preserves the integrity of your operations. The role of crating in machinery transport can't be overstated—it's the difference between equipment arriving in perfect working order or facing costly repairs and delays.

Ryan joined the Boulter team in 2016 as a field employee before transitioning to Packaging Shop Supervisor and now Project Manager. With his diverse background in the field and the crating and packaging shop, he is well-equipped to handle the complexities and challenges that come with managing projects of varying scales and requirements.