Choosing the Right Industrial Contractor for Your Project

We’ve all heard choosing the right industrial contractor is a lot like dating—you don’t want to settle for the first one who shows up with a hard hat and a handshake. Okay, maybe no one says that, but the point still stands. If you’ve never experienced the pain of a project gone wrong, consider yourself lucky. The truth is that the wrong choice can lead to delays, headaches, and a lot of wasted money. Selecting the right contractor isn’t just about finding someone who checks the boxes for solutions, cost, and reliability—it’s about finding the one that’s the best fit for your unique needs. So, how do you figure that out? Let’s dive in.

Define Your Project Needs

Expanding operations, adding new equipment, or retrofitting a production line to increase capacity all require one crucial first step: clearly defining the scope of your project. Before you even start researching contractors, it's essential to have a full understanding of what the job entails. This clarity will guide your decision-making, ensuring you select a contractor with the right expertise and specialization to handle the task at hand.

By defining your project needs upfront, you can narrow your search to contractors who are best suited to handle your specific requirements. This will save you time, money, and the frustration of hiring someone who isn't equipped for the job.

Key questions to ask yourself:

- What is the timeline for the project? Is it a quick turnaround or a long-term engagement?

- What types of machinery or services are needed? Are there any highly specialized skills or equipment involved?

- Is this a one-time project, or will ongoing maintenance and support be required after completion?

This process helps you not only clarify your needs but also avoid ending up with a contractor who can’t fully meet them. For instance, you might start out thinking you just need someone to install new equipment, but as the project moves forward, you realize your site isn’t ready and you need storage for the machinery. Choosing a contractor with a broader range of services—such as warehousing, trucking, and rigging—can save you from scrambling to find additional help later, making the entire process more efficient and cost-effective.

Taking the time to define the full scope of your project helps ensure you find a contractor who can meet your current and future needs, saving you the hassle of managing multiple vendors and piecemeal solutions.

Look for Experience in Your Industry

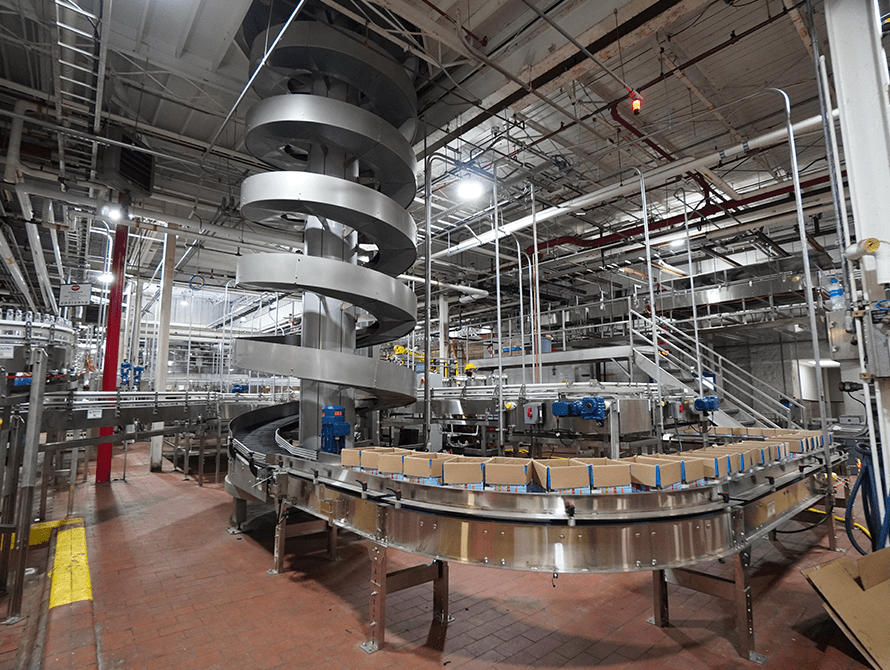

It’s not just about whether a contractor can get the job done—it’s about whether they’ve faced the specific challenges unique to your industry and come out the other side successfully. After all, you wouldn’t hire a company with zero experience in food and beverage plants to install complex conveyor systems for a brewery, right? That’s a recipe for disaster.

Specialty contractors often have a wide range of skills, but many choose to focus on a few select industries where they truly excel. Contractors with industry-specific experience know the common pitfalls, regulations, and nuances that come with the territory.

Finding a contractor who understands the ins and outs of your industry means they’re more likely to anticipate potential issues before they arise, from regulatory hurdles to safety concerns. They’ll already be familiar with best practices and industry standards, which means fewer surprises—and fewer headaches for you.

Check Safety Records and Certifications

Safety isn’t just a buzzword; it's a non-negotiable in any industrial project. In an industry where heavy machinery and high-risk environments are the norm, you can't afford to work with a contractor who doesn't prioritize safety. You wouldn’t want to see a team show up at your site without proper gear—or worse, in sneakers. A contractor that takes safety seriously ensures their team is well-trained, equipped with the right personal protective equipment (PPE), and prepared to handle the inherent dangers of the job.

At Boulter, we believe there’s nothing more important than ensuring every employee returns home safely at the end of the day. This focus on safety doesn’t just protect workers, it protects your project timeline and budget, too. A safe worksite means fewer accidents, less downtime, and smoother execution from start to finish.

When vetting potential contractors, it’s crucial to look into their safety track record and certifications. Key certifications, such as OSHA 10 or OSHA 30, demonstrate a company’s commitment to safety training. Specialized certifications, like certified crane signal persons, ensure the contractor’s team can handle the complexities of your project safely and efficiently.

A company's safety record reflects its dedication to minimizing risks on-site. Contractors with clean safety records and rigorous safety programs have already proven their ability to execute projects with minimal incidents. This not only gives you peace of mind but also reassures you that your project won’t suffer from preventable delays or added costs due to safety violations.

Review Their Equipment and Technology

The quality of a contractor's equipment is equally as important as the team using it. What’s the use of having the A team working on outdated, faulty equipment? Modern, well-maintained equipment is a critical factor that can impact the precision, speed, and overall success of your project. Relying on outdated or poorly maintained machinery is like expecting a flip phone to stream HD video. Sure, it might get the job done eventually, but you’ll be left frustrated with delays and inefficiencies.

Contractors that invest in advanced equipment, like hydraulic gantry systems, forklifts, Lowboy trailers, and other specialized machinery, bring a higher level of precision and capability to the table. Hydraulic gantries, for example, allow for controlled lifting of heavy loads in tight spaces, while Lowboy trailers are essential for transporting oversized equipment without risking damage. These tools aren't just bells and whistles—they ensure that projects are handled with care and accuracy. Leveraging the latest equipment also reduces downtime, limits the risk of damage to sensitive machinery, and keeps everything running on schedule. When reviewing contractors, don’t just ask what equipment they have—ask how they maintain it, and whether they’re using the latest technology to ensure your project goes off without a hitch.

In addition to equipment, contractors who embrace the latest technological advancements are even better positioned to deliver top-notch service. This can include the adoption of AI to streamline processes, improve efficiency, or even predict potential issues before they arise. Technologies like CRM systems for managing customer interactions and job scheduling software to keep projects on track provide a seamless experience, ensuring you're in the loop every step of the way. With these tools at their disposal, contractors can offer better transparency, faster response times, and a more efficient project from start to finish.

Evaluate Communication and Project Management Skills

Clear, consistent communication can make or break your experience with an industrial contractor. You could be working with the most skilled team in the business, but if their communication is lacking, you’ll find yourself wondering where your project stands, what issues might be cropping up, and whether deadlines are slipping. Good communication isn’t just a “nice-to-have”—it’s essential for staying on track and ensuring your project runs smoothly.

Transparency is key at every stage, from the initial quoting process to execution and final completion. No one likes to be left in the dark, and the best contractors know that keeping clients informed builds trust and confidence. You should never be left guessing about timelines, costs, or potential issues. Whether it's updating you on milestones, alerting you to unexpected challenges, or just touching base to ensure everything is on track, a contractor’s ability to communicate clearly and proactively makes all the difference.

This communication should start as early as the request for a quote (RFQ) and continue through job completion—and ideally, beyond. It’s more than just delivering a service; it’s about building a relationship for future projects. When contractors provide open, honest communication, they aren’t just keeping you informed—they’re demonstrating a level of customer service that builds long-term partnerships.

This is where having a dedicated project manager becomes crucial. A good contractor will assign someone to oversee the entire project, troubleshoot any issues, and keep you in the loop. The project manager acts as your point person, ensuring that everything is progressing as planned and that any concerns are addressed before they become major problems. They’re there to manage the details so you don’t have to, giving you peace of mind and allowing you to focus on other areas of your business.

Consider Their Reputation and References

A company’s track record is a direct reflection of how they’ll handle your project. One of the best ways to do this? Ask for references, customer testimonials, and case studies. Trust me, if they have a marketing team, they're probably dying for you to ask about their case studies. It’s not just about showing off; these real-world examples offer a glimpse into how the contractor handles projects similar to yours and how reliable they truly are.

And don’t stop at the shiny, curated marketing materials. Head over to Google and see what people are saying. Authentic reviews can give you insight that a polished case study might not—look for patterns in the feedback, both good and bad. Are clients raving about their communication skills and timeliness, or are there consistent complaints about missed deadlines and lack of follow-up?

Talking to previous clients is also invaluable. It gives you a chance to ask about the contractor’s strengths, but more importantly, their areas for improvement. Maybe the contractor did a great job on a complex rigging project but struggled with keeping the client updated on progress. These details can help you decide if the contractor's approach fits your needs and working style.

Price Isn't Everything—Focus on Value

There's a saying we love: "Quality costs, but poor quality costs more." Sure, sometimes the cheaper option might seem like a win—until it isn’t. Maybe you luck out once and the budget contractor pulls off the job without a hitch. But more often than not, cutting corners comes with risks that can lead to bigger, more expensive problems down the road.

The cheapest option might look good on paper, but that price tag doesn’t always reflect what you’re really getting. When contractors offer lower prices, they might be cutting costs by using outdated equipment, hiring less experienced workers, or skimping on safety measures. What happens when those decisions lead to delays, faulty installations, or even workplace accidents? Suddenly, your "bargain" choice becomes a nightmare, with expensive fixes, potential injuries, and major project delays piling up.

Evaluating value means looking beyond the initial price. Consider the contractor’s expertise, the quality of their equipment, their track record for meeting deadlines, and how well they plan for long-term success. A company that invests in advanced technology, highly trained staff, and strict safety standards is more likely to deliver a project that runs smoothly and stands the test of time. It may cost more upfront, but it saves you from the hassle and additional expenses of rework and extended downtime.

Blog: The True Cost of Quality

For example, imagine choosing a contractor based solely on price, and they send an underqualified team with outdated equipment to install a production line. As a result, the project is delayed, equipment is damaged, and you’re left scrambling to find another contractor to fix the mess—while your plant sits idle, losing money every day. Compare that to paying a bit more upfront for a team with modern equipment and specialized skills. The job gets done right the first time, ahead of schedule, and you’re back in production without a hitch. The initial cost might be higher, but the long-term savings—in time, money, and stress—are undeniable.

At the end of the day, it's about weighing the full scope of value. Quality, safety, expertise, and efficiency all factor into making the right decision for your project. In the industrial world, value always outweighs a quick, cheap fix.

Conclusion

Choosing the right industrial contractor is about more than just finding the lowest bidder or the biggest name. It’s about making sure you have a partner who understands your industry, prioritizes safety, communicates, uses the right equipment, and brings real value to the table. A reliable contractor will not only get the job done but will help you avoid costly mistakes, minimize downtime, and keep your project running smoothly from start to finish.

While it might be tempting to go with the cheapest option, remember that the long-term costs of poor quality can far outweigh any short-term savings. Take the time to evaluate your needs, vet potential contractors thoroughly, and focus on the overall value they can bring to your project. When you do, you’ll find that the right contractor is not just an expense—it’s an investment in your success.

If you're ready to partner with a contractor that checks all these boxes and more, reach out to our project management team. We’re ready to talk about how we can help make your next project a success, from concept to completion.

Brittany joined the Boulter team in 2017, following her experiences in the entertainment and healthcare sectors. In her role as Marketing Manager, she oversees all aspects of Boulter's brand management and digital marketing initiatives. However, her passion extends beyond these responsibilities. Brittany is an advocate for encouraging younger generations to explore rewarding career opportunities in the trades, addressing the critical issue of labor shortage.